Monitoring and control software for wind turbines

Providing O&M teams with SCADA software for real-time monitoring and remote control of wind farms, reducing unnecessary site visits.

Get WindSync

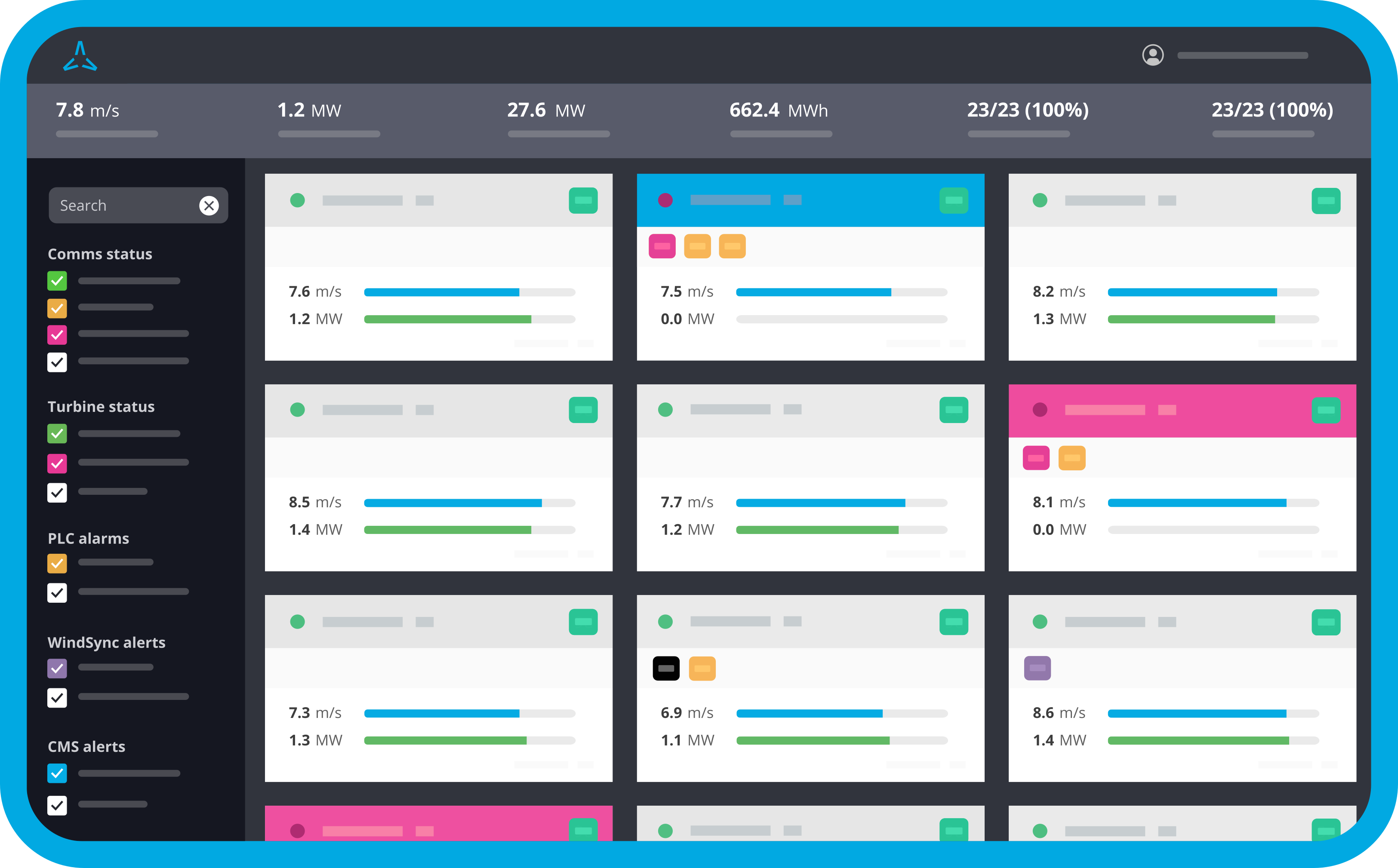

Operate your sites with ease

WindSync works on a browser or mobile device so that users can keep track of sites from the office or on the road.

Cyber security in wind SCADA is paramount. WindSync uses secure cloud servers and VPN technology to ensure data is secure.

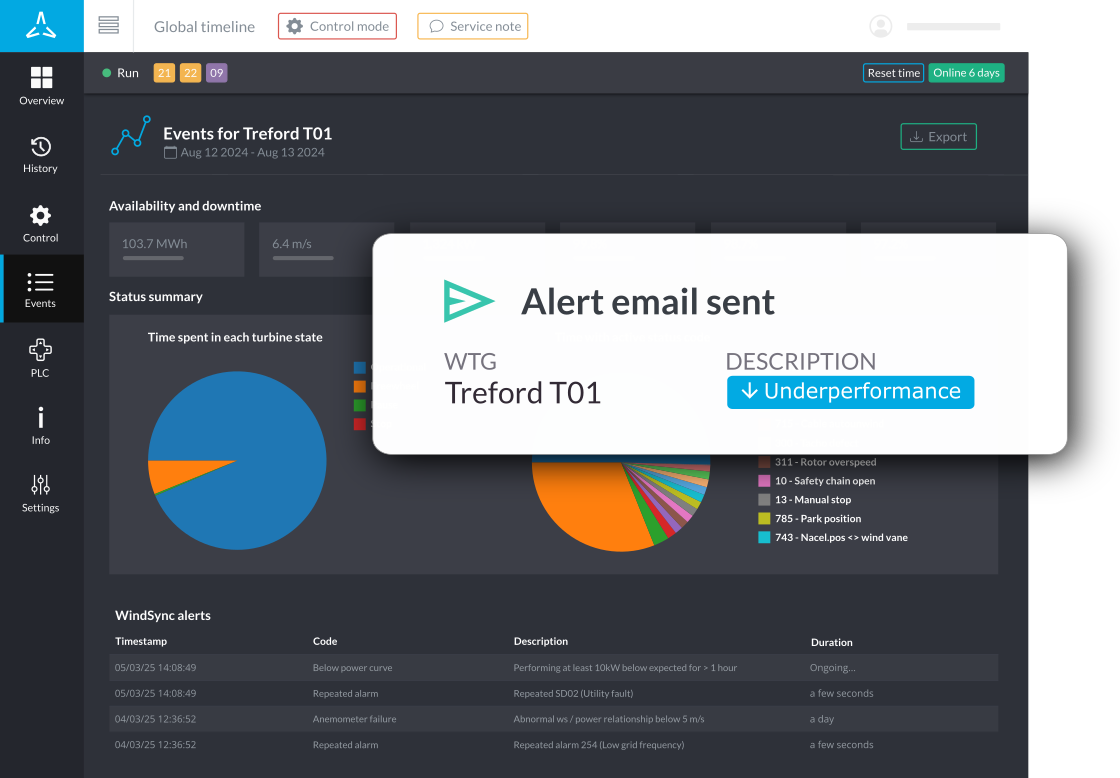

Never miss an issue

Some turbine issues are not detected by the turbine control system.

WindSync alerts pick up issues that would otherwise go unnoticed. From sensor failure to power curtailments to over production, WindSync helps ensure that monitoring teams never miss an issue.

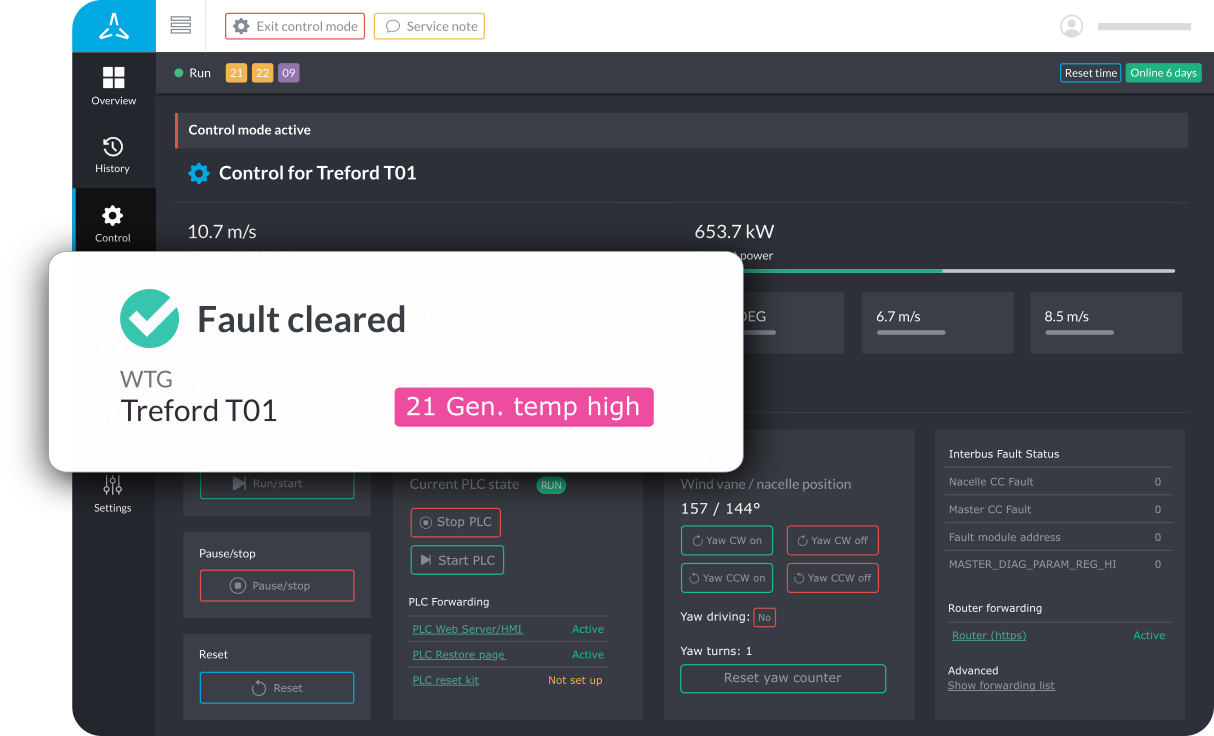

Eliminate unnecessary site visits

WindSync SCADA provides full supervisory control including fault clearance, setpoint configuration. It also helps with those site specific tasks that eat up time such as remote G59 resets, noise/flicker management and PLC clock syncing.

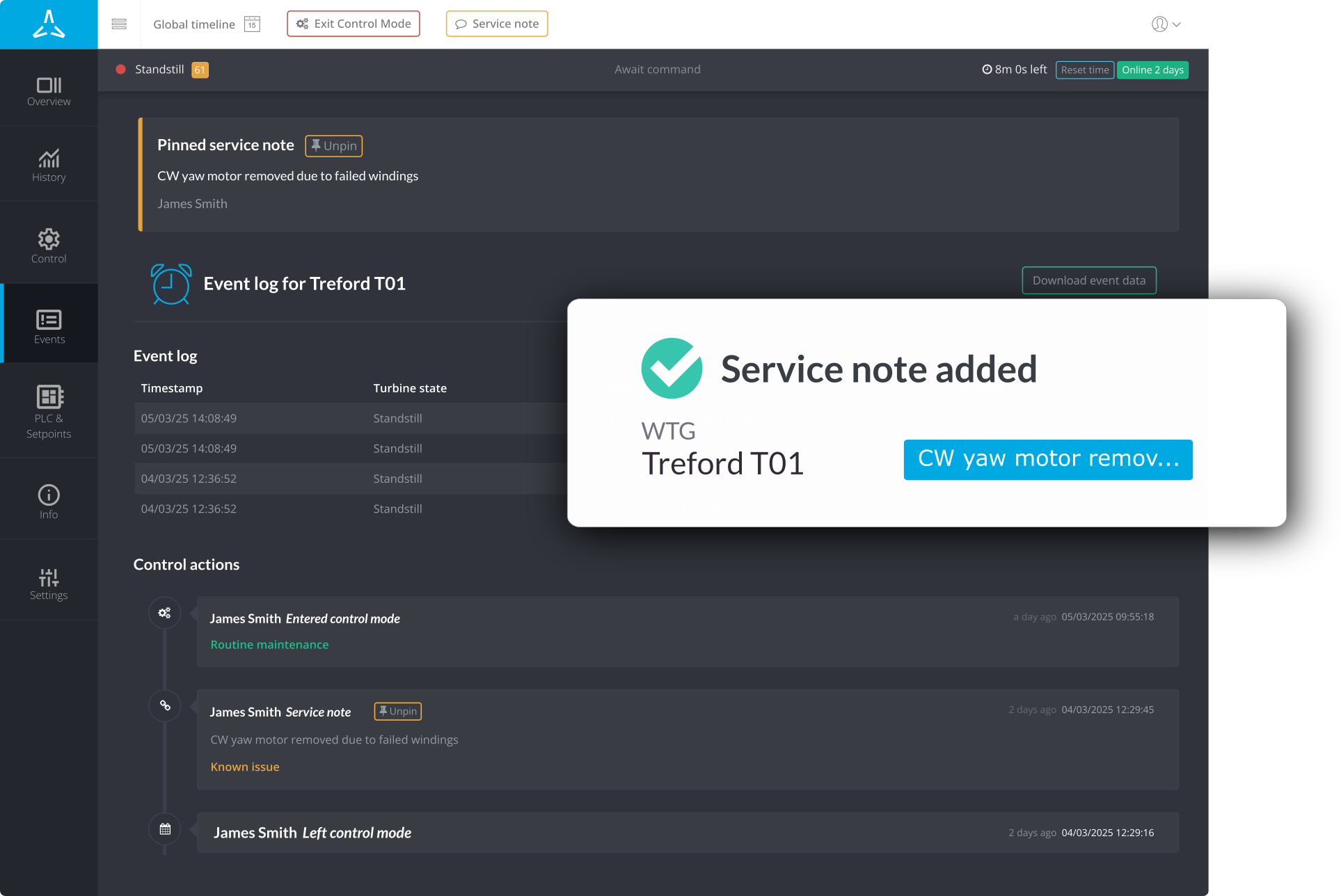

Keep track of site activity

All user actions are recorded and displayed in WindSync alongside the event log. Notes, tags and groups allow control room teams and site technicians to track key site events and information.

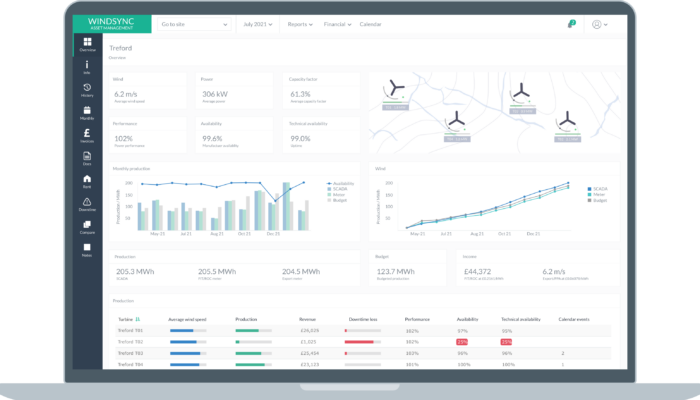

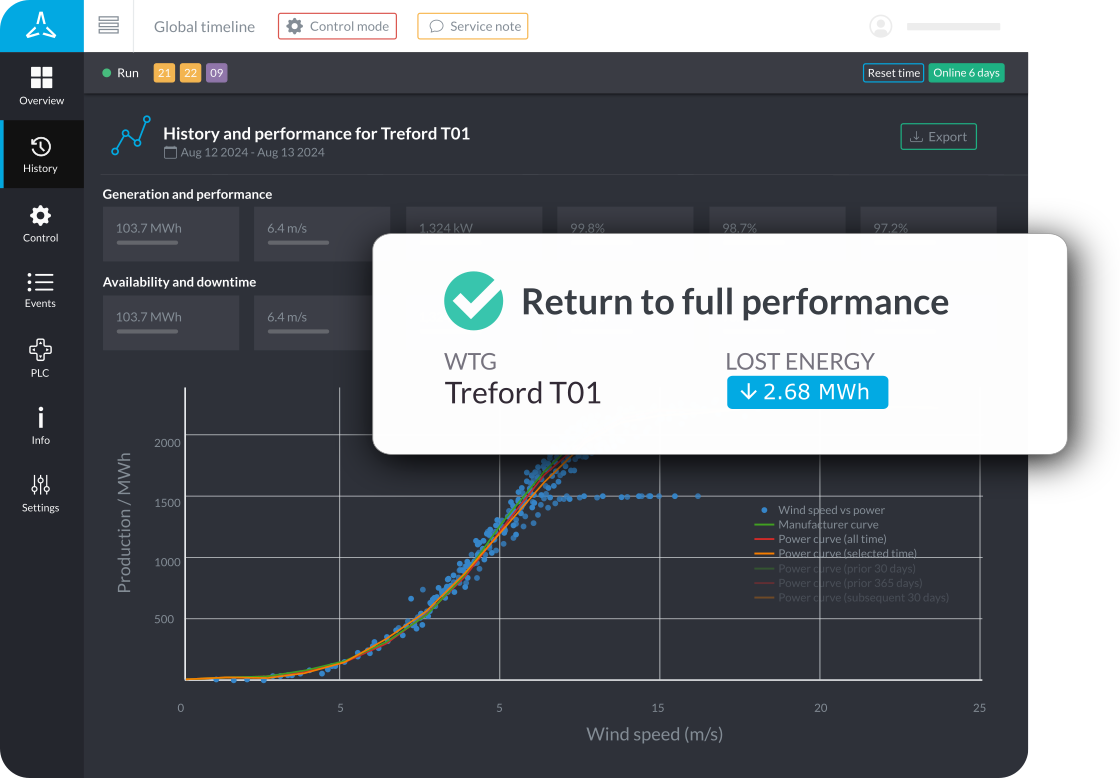

Analyse performance and downtime

WindSync identifies under performance issues and quantifies lost energy due to underperformance and downtime

“Invaluable 24/7 access”

The system provides us with invaluable 24/7 access to real-time monitoring, data creation, fault clearance, parameter configuration, performance, and downtime analysis. With instant access available to all key personnel including our wind farm owner, our operations control room and service teams, WindSync ensures we can always monitor our assets through the simple to use web-based platform. Many thanks to Peter and his team at Visualwind for providing a smooth install and bespoke training package.

Rob Payne, Commercial Director Galetech Group/Director at Adamas

FAQs

For in-warranty wind sites, the OEM will use their own SCADA software. However, once the site is no longer in warranty with the OEM, it is likely that an independent service provider (ISP) will be engaged to operate and service the machines. In such circumstances, the original OEM SCADA system may be removed or no longer supported and it is necessary to install an alternative. In other cases, the OEM SCADA system may remain in place but there is value in using newer SCADA software which accords to modern communications and cyber security best practice and is supported by a service and support team.

WindSync is compatible with serval types of wind turbine including Vestas, Endurance, Powerwind, Bonus, Micon and several others. If you are looking for a retrofit SCADA solution and want to know if WindSync will work with your sites, contact us and we will let you know.

SCADA (Supervisory Control and Data Acquisition) is distinct from the wind farm control systems in that it does not handle the routine operation of the wind turbine equipment. Instead it provides a way for users to interact with the control system including monitoring, control and data analysis. The control functions in SCADA software are limited to those permitted by the control system including things like, stop, start, reset and changing of setpoints or parameters. The SCADA software setup will vary between different SCADA systems and different control systems but normally there will be some SCADA hardware at the wind farm which communicates locally with the wind turbine controllers and also with a cloud server?

Gradual changes in turbine performance can be hard to spot. WindSync helps identify these performance degradations with SCADA data shown alongside manufacturer and long-term power curves and lost production calculations.

Yes WindSync processes the event log into downtime events and plots so you can easily see major causes of downtime and the impact on production.

Renewable energy operators need data to move between different systems in real time. WindSync sends and receives data to third party systems such as CMS and predictive maintenance software via the WindSync API. WindSync also works seamlessly with our Renios renewable energy management software.