There are several hundred Vestas wind turbines in the UK. Many of these have been installed in recent years and are operated and maintained by Vestas. However, a significant number of Vestas turbines in the UK are several years old and are operated and maintained by independent service providers (ISP). For such sites, operators may chose to use independent SCADA software.

Why use independent SCADA software?

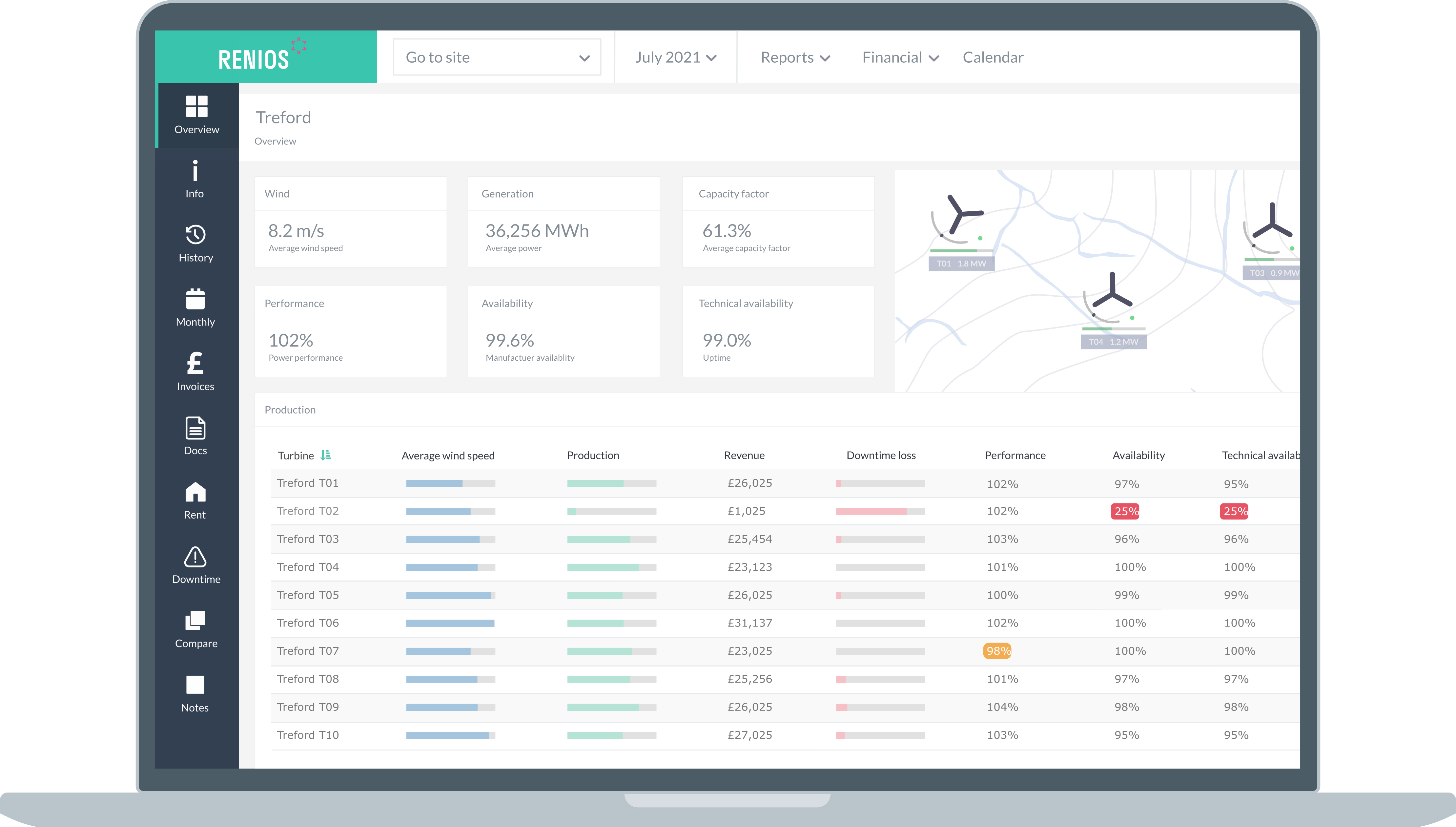

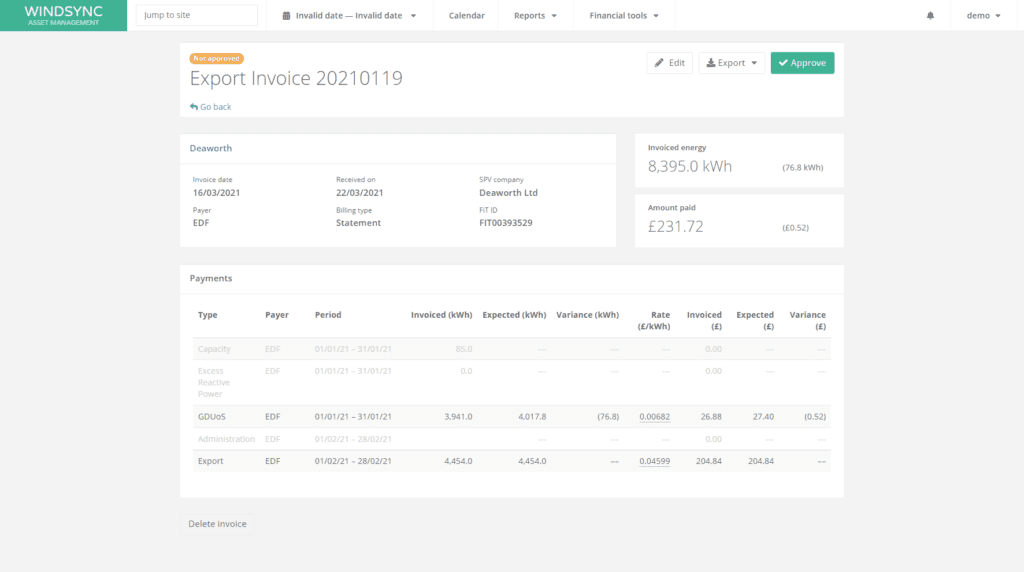

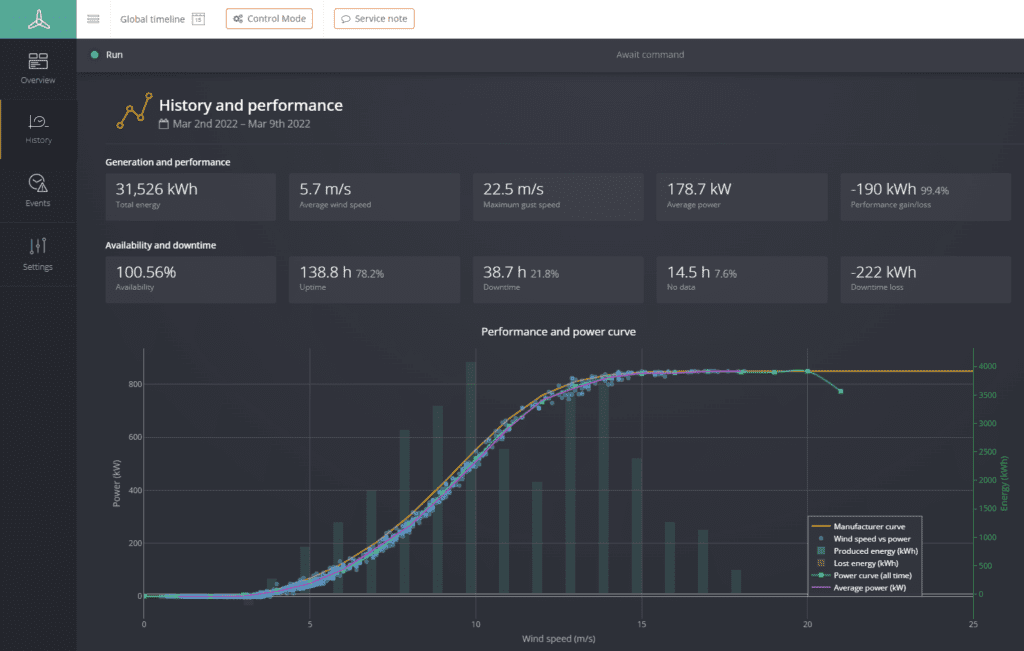

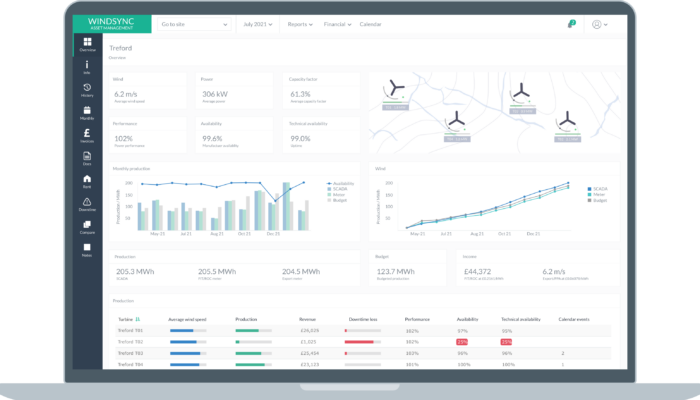

There are several motivations for using independent SCADA software. For older sites, the original SCADA system may no longer be available – or it may be unsuitable for modern 24/7 monitoring. An independent SCADA system can bring the benefits of modern, software making it easy monitor sites while maintaining a high level of security.

How independent SCADA software works

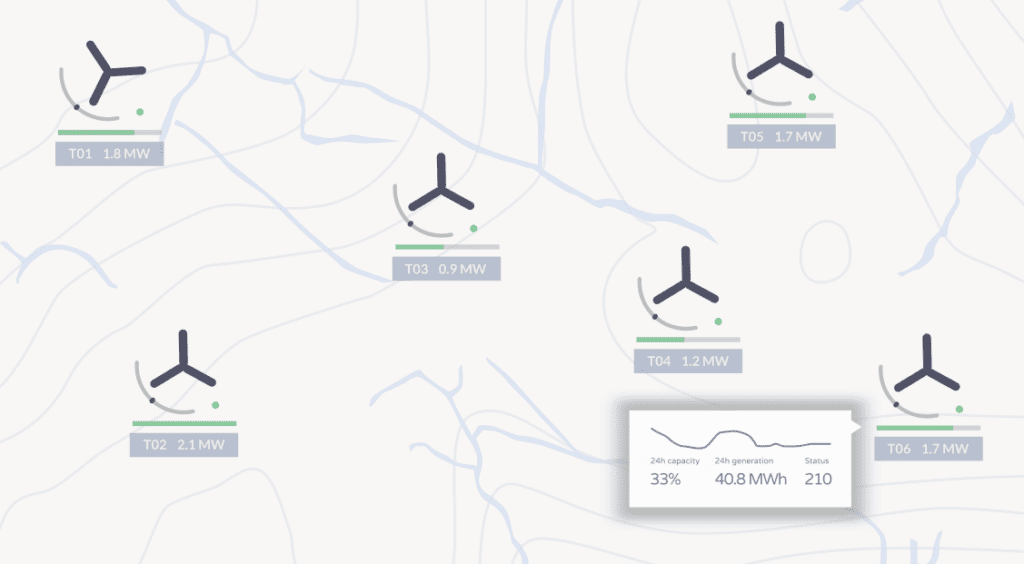

Independent SCADA software works by acting as a bridge between the original wind turbine equipment and the outside world. Typically equipment is installed at the wind farm or wind turbine which connects to the wind turbine controllers and sends data to a remote server via a VPN connection.

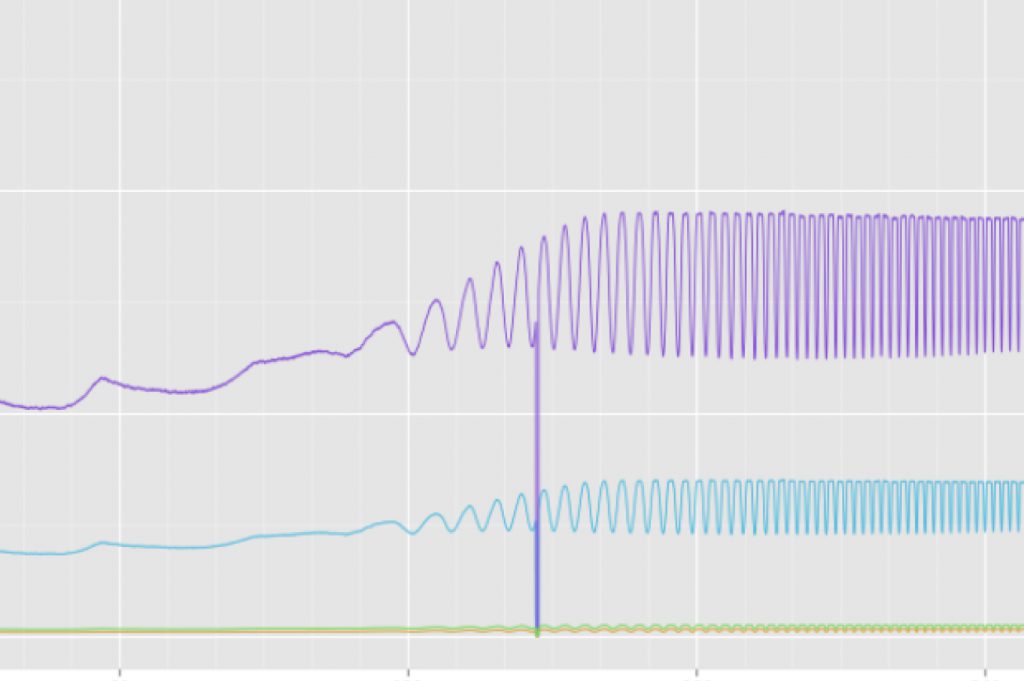

Older Vestas turbine controllers do not store 10-minute data so it is necessary for the independent SCADA software to create this data. Wind turbine data is requested at frequent intervals and aggregated into 10-minute average data and event log data. Key monitoring data including wind speed, power, active alarms and turbine status are transmitted live for real-time monitoring.

In addition to creating 10-minute and event log data, the independent SCADA software can access the data that is stored on the turbine controllers including logs and monthly counters.

Does the turbine controller need to be replaced?

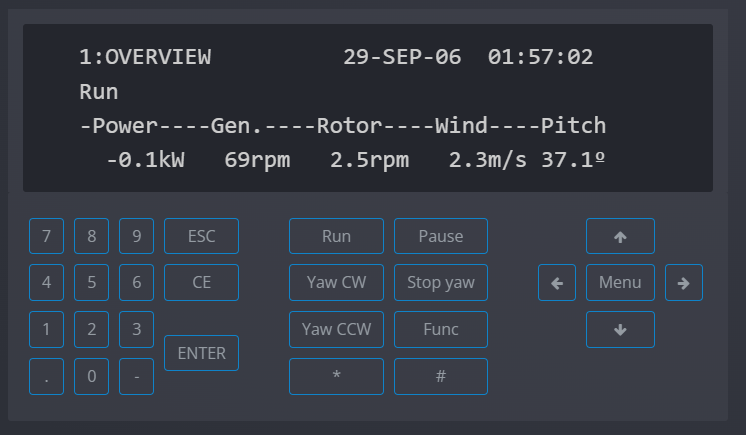

No. Independent SCADA software communicates with the existing Vestas controllers so there is no change to the control equipment or the behaviour of the turbines. At some sites, the operators choose to replace the turbine controllers with newer equipment such and where this is the case, the SCADA software is configured to communicate with the relevant controller type.

Can you clear faults remotely?

Yes you can use Independent SCADA software to remotely clear faults at Vestas wind turbines. It is also possible to provide remote access to the panel for some Vestas turbine for enhanced control functionality.

For more information about independent SCADA software, read about our WindSync software or contact us.